Eflute packaging is a quick, smart, yet cost effective way to brand your packaging.

We mount 200gsm laminated prints onto eflute, die cut to shape and then make up into the relevant packaging. We can create a design specifically for your product or you can choose from a wide range of existing cutters.

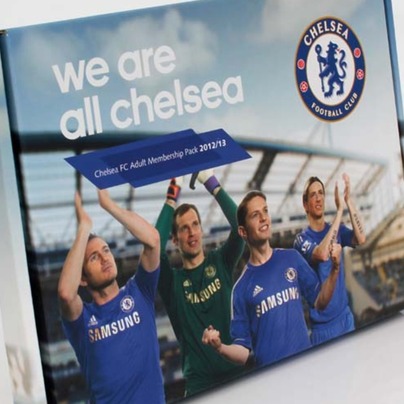

Case Study 1

Client: Chelsea Football Club

Product: Membership pack

We have been working with Chelsea Football Club for a number of years now. The size and design of the pack remains the same, but the artwork changes each year. We mount laminated prints onto eflute, die cut to shape and supply flat to be made up by the client. These are then sent out as membership packs.

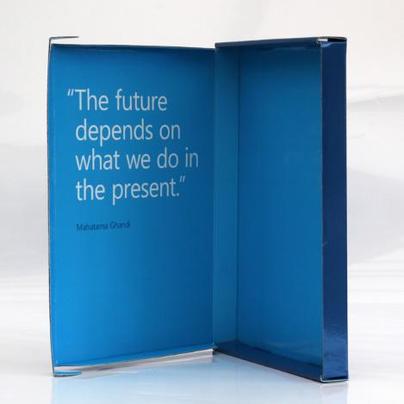

Case Study 2

Client: Printer

Product: Careers Toolkit

Our client supplied us with laminated prints which we then mounted onto both sides of the e-flute and die cut to shape. The final product was supplied flat to be made up by the client

Case Study 3

Client: Marketing Agency

Product: Mailing carton with sleeve

This product is very similar to the one above, but has a printed sleeve around the mailing carton. The sleeve is is 350gsm printed, laminated card, die cut to shape and glued to form a sleeve. We supplied these made up with the sleeve in place.

Case Study 4

Client: Design Agency

Product: Retail display unit

The client came to us with the concept of how to pack and display dog bones and treats in a retail environment. This pack has a tear strip around the middle which creates two trays from the one pack, thus saving the client considerable amounts of money. 200gsm gloss prints were mounted onto eflute and then die cut to shape (including the tear strip), we then creased and glued the eflute to make a flat 3D product, to be made up and fulfilled by the client.

Case Study 5

Client: Marketing Agency

Product: Promotional mailing carton

This was manufactured in the same way as the previous items, but it is a sightly larger finished size, and has a bespoke die cut tray to hold the various promotional items that were sent out in the box.

Case Study 6

Client: Engine Car Part Supplier

Product: Car part packaging

We mounted 200gsm laminated prints onto eflute, die cut to shape and stuck down glue flap to form flat 3D shape. This is a much smaller box to the above.

Case Study 7

Client: Printer

Product: Pharmacy Starter Pack

We created the carton in the same way as the other examples, but this time we also manufactured the contents of the box – a strutted show card and a leaflet dispenser. We supplied the boxes made up and filled with the contents.